Extruded Aluminum Panels: Innovative, Reliable Solutions for Modern Projects

Introduction to Extruded Aluminum Panels

Imagine a material that combines strength, durability, and beauty, all while being lightweight and versatile. Sounds ideal for modern construction, right? Enter extruded aluminum panels, a revolutionary solution that is reshaping the landscape of contemporary architecture and design. These panels have become a cornerstone in the construction industry, thanks to their unmatched versatility and aesthetic appeal.

Extruded aluminum panels are crafted through a process that allows for intricate designs and shapes, making them a favorite among architects and builders. Their growing popularity is not just a trend but a testament to their functionality and the innovative possibilities they offer. These panels are used extensively in building facades, interior partitions, and even in decorative applications. What makes them stand out is their ability to seamlessly blend with any design, offering both form and function.

In the realm of modern construction materials, extruded aluminum panels are prized for their lightweight nature, which simplifies transportation and installation, reducing overall project costs. Their corrosion resistance ensures longevity, making them an ideal choice for outdoor applications exposed to the elements. Furthermore, their aesthetic versatility allows for a wide range of finishes and colors, enabling architects to achieve their desired look without compromising on structural integrity.

As the demand for sustainable and efficient building materials rises, extruded aluminum panels are at the forefront, offering a recyclable and energy-efficient option. Their ability to be recycled without losing quality makes them a sustainable choice, aligning with the industry's shift toward eco-friendly practices. In essence, extruded aluminum panels are not just a material choice but a strategic decision that enhances both the functionality and visual appeal of modern projects.

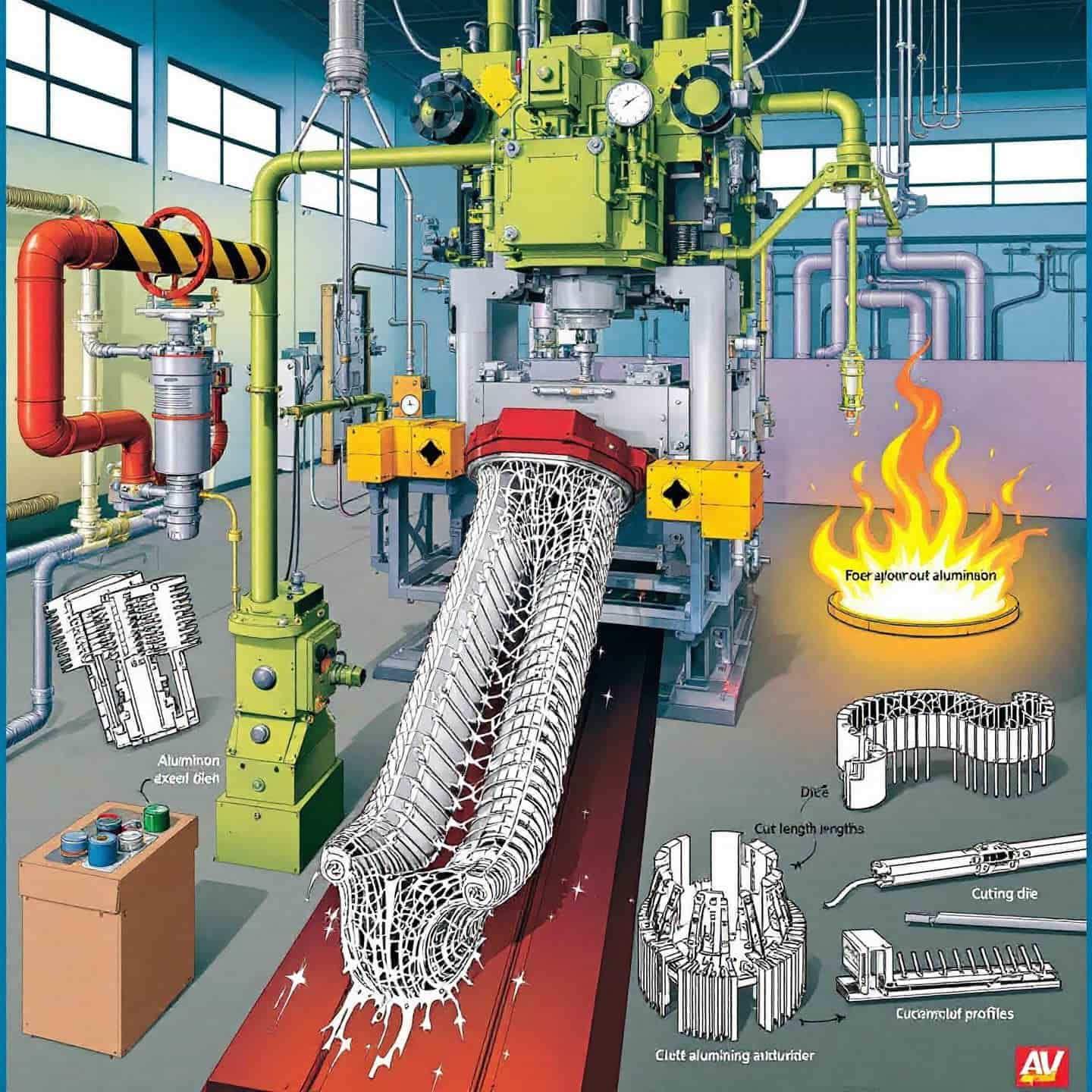

Understanding Extruded Aluminum Panels

Extruded aluminum panels are at the heart of modern architectural innovation, but what exactly are they? These panels are crafted through an aluminum extrusion process , a technique that involves pushing heated aluminum alloy through a shaped die to create profiles with specific cross-sectional designs. This process allows for the creation of complex shapes that are both solid and hollow, catering to a wide range of construction needs.

One of the standout features of extruded aluminum panels is their lightweight nature. Compared to traditional materials like steel or wood, aluminum is significantly lighter, which translates to easier handling and reduced transportation costs. This characteristic is particularly advantageous in large-scale projects where the ease of installation can lead to substantial savings in both time and labor.

Corrosion resistance is another critical advantage of these panels. Aluminum naturally forms a protective oxide layer that shields it from the elements, making it an excellent choice for outdoor applications where exposure to moisture and pollutants is a concern. Moreover, additional surface treatments such as anodizing can further enhance this protective layer, improving the panels' durability and lifespan.

Design flexibility is where extruded aluminum truly shines. The extrusion process allows for the creation of intricate designs that can be customized to meet specific architectural requirements. Whether it's for sleek, modern facades or more traditional styles, these panels offer unparalleled versatility. They can be finished in a variety of ways, including powder coating and painting, to achieve the desired aesthetic while maintaining structural integrity.

In summary, extruded aluminum panels offer a combination of lightweight strength, corrosion resistance, and design flexibility that makes them superior to many traditional building materials. As the construction industry continues to evolve, these panels are set to play an increasingly vital role in shaping the future of architecture and design.

Applications of Extruded Aluminum Panels

Extruded aluminum panels are revolutionizing various sectors with their unique properties and versatility. These panels are increasingly becoming the go-to choice for architects and builders due to their adaptability across a wide range of applications. Let's delve into some of the exciting ways these panels are being utilized in modern construction and design.

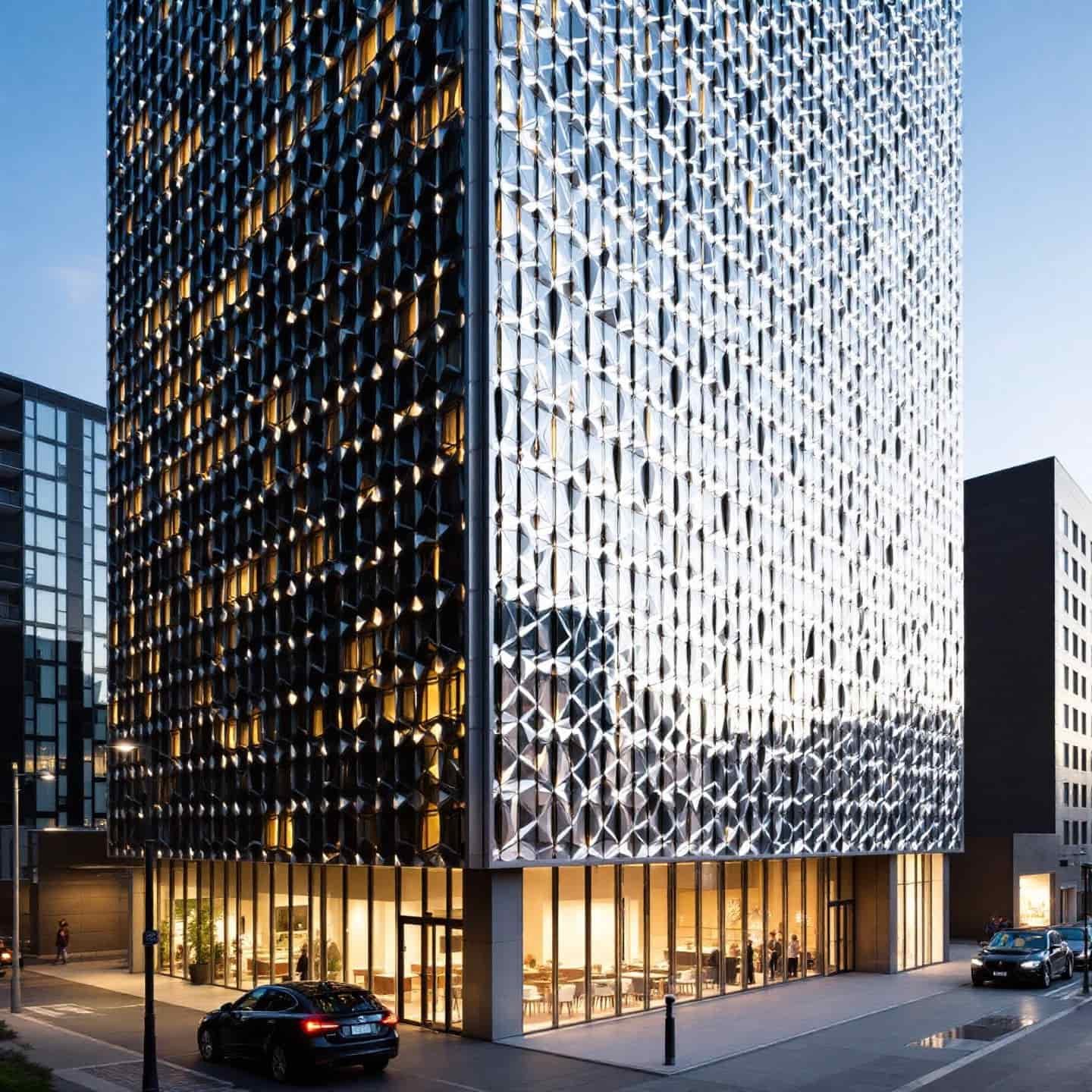

Aluminum Wall Panels for Building Facades

Imagine a sleek, modern building facade that not only looks stunning but also stands the test of time. That's the promise of aluminum wall panels. These panels are ideal for creating visually striking exteriors that offer both aesthetic appeal and durability. Their lightweight nature makes them easy to install, while their corrosion-resistant properties ensure they maintain their appearance even in harsh weather conditions. Moreover, the design flexibility of extruded aluminum allows for various textures and finishes, enabling architects to achieve a wide range of styles, from ultra-modern to classic.

Industrial Aluminum Flooring Solutions

In industrial settings, flooring needs to be robust, durable, and capable of withstanding heavy use. Extruded aluminum panels meet these requirements perfectly. These panels provide a strong, lightweight solution that can support significant weight without compromising on safety or durability. Their resistance to corrosion and wear makes them ideal for environments where floors are exposed to chemicals or moisture. Additionally, they offer excellent thermal conductivity, which can be beneficial in temperature-controlled environments.

Sign Panels for Customization and Weather Resistance

Signage is another area where extruded aluminum panels shine. Thanks to their smooth surface and customizable nature, these panels are perfect for creating vibrant, eye-catching signs that can withstand outdoor elements. Whether it's for retail signage, billboards, or directional signs, aluminum panels offer a durable and visually appealing solution. Their ability to be painted or coated in various colors and finishes means they can be tailored to fit any branding requirement, ensuring that businesses can maintain a consistent and professional appearance.

In conclusion, the applications of extruded aluminum panels are vast and varied. They offer innovative solutions for building facades, industrial flooring, and signage, among other uses. As industries continue to seek materials that combine durability, versatility, and aesthetic appeal, extruded aluminum panels are poised to become an even more integral part of modern construction and design strategies.

Specialized Extruded Aluminum Panel Components

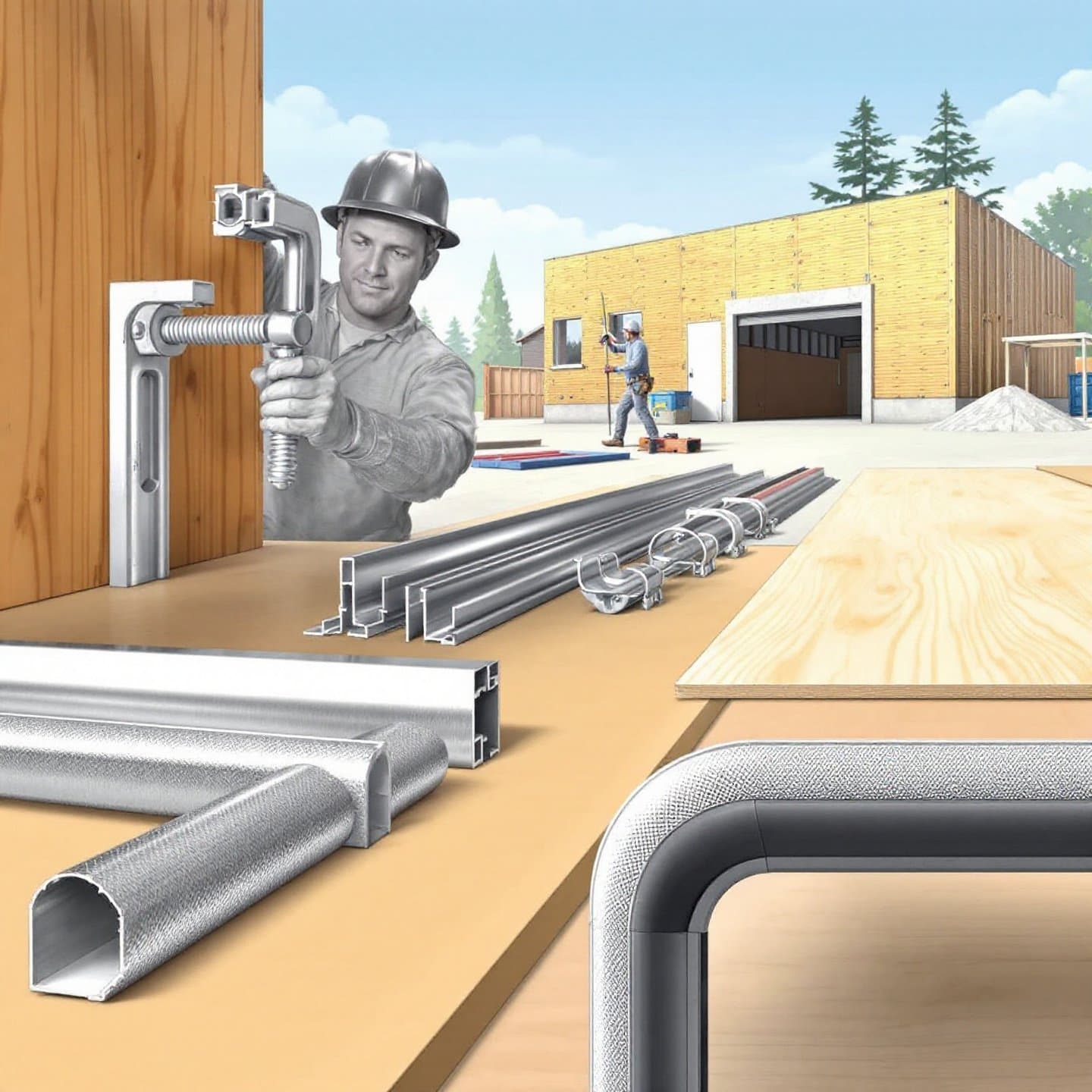

When it comes to securing extruded aluminum panels, specialized components like aluminum panel clips and trims play a pivotal role. These components not only ensure that panels are securely fastened but also enhance the overall design aesthetics of a project.

Aluminum Panel Clips: Secure and Efficient

Imagine the ease and efficiency of installing panels that require minimal effort yet provide maximum stability. That's the promise of aluminum panel clips. These clips, such as the renowned Eagle-Clip Z Clips, are engineered for strength and ease of use. Made from heat-treated hardened aluminum, they offer exceptional holding power, making them ideal for hanging wall panels, partitions, and even artwork.

- Quick Installation: Aluminum panel clips allow for fast mounting and removal, reducing installation time significantly.

- Versatile Applications: Suitable for both residential and commercial projects, these clips can hold a variety of panels, including acoustical and decorative types.

- Durability: Designed to withstand substantial weight, some clips can support loads of up to 478 lbs, ensuring safety and stability in any application.

For more information on the capabilities and specifications of aluminum panel clips, you can explore detailed resources such as Eagle Aluminum's guide .

Aluminum Panel Trim: Enhancing Aesthetic Appeal

Beyond securing panels, aluminum panel trim is crucial for adding a polished finish to any project. These trims frame panels neatly, providing a seamless transition between different materials and enhancing the visual appeal of the installation.

- Customizable Finishes: Available in various finishes such as anodized or powder-coated, aluminum trims can be tailored to match any design style.

- Corrosion Resistance: Like the panels they complement, aluminum trims resist corrosion, ensuring longevity and reducing maintenance costs.

- Ease of Installation: Lightweight and easy to handle, these trims simplify the installation process, making them a favorite among builders and architects.

Whether you're aiming for a modern look or a more traditional style, aluminum panel trims provide the flexibility needed to achieve your design vision. For further insights into the benefits and applications of aluminum trims, you might find this detailed article helpful.

In summary, the integration of aluminum panel clips and trims in construction projects not only ensures structural integrity but also elevates the aesthetic quality of the final product. As we move forward, these components will continue to be indispensable in creating both functional and visually appealing structures.

Innovative Uses of Extruded Aluminum Panels

When envisioning modern architectural designs, versatility and innovation are key. Extruded aluminum panels are at the forefront of this creative evolution, offering cutting-edge solutions such as LED backlit panels and modular systems that redefine conventional uses. Let's explore how these innovations are transforming spaces with their unique features and benefits.

LED Aluminum Panels: Illuminating Design

Imagine walking into a space where the walls themselves glow, creating an ambiance that captivates and inspires. LED aluminum panels are making this a reality. By integrating LED lighting into aluminum panels, architects can achieve stunning visual effects that enhance both interior and exterior spaces. These panels are particularly popular in environments where ambiance and aesthetics are crucial, such as in retail spaces, corporate offices, and hospitality venues.

LED backlit panels offer a seamless way to highlight architectural features, logos, or even art installations. They provide consistent illumination across surfaces, making them ideal for creating dramatic effects or subtle highlights. According to Accurate Perforating , these panels can be customized with various lighting options, including different colors and intensities, allowing for personalized design solutions that meet specific project requirements.

Modular Aluminum Systems: Flexibility and Efficiency

In the realm of construction, efficiency and adaptability are paramount. Modular aluminum systems offer a flexible solution that meets these demands. These systems consist of prefabricated panels that can be easily assembled and reconfigured, making them perfect for projects that require quick installation and future adaptability.

Modular systems are designed to be both cost-effective and sustainable. They utilize recycled materials and offer a range of customization options, from solid to perforated designs, as detailed by Americlad . This adaptability allows for endless design possibilities, catering to both aesthetic and functional needs. Whether used for facades, partitions, or cladding, these systems provide a streamlined installation process that reduces labor costs and minimizes waste.

In conclusion, the innovative applications of extruded aluminum panels, such as LED backlit panels and modular systems, are revolutionizing the way we think about design and construction. By offering unparalleled versatility and ease of assembly, these panels are not only enhancing the aesthetic appeal of spaces but also contributing to more efficient and sustainable building practices. As technology and design continue to evolve, extruded aluminum panels will undoubtedly play a pivotal role in shaping the future of architecture.

Selecting the Right Extruded Aluminum Panels for Your Project

Choosing the right extruded aluminum panels for your project can significantly impact the success of your construction or design endeavor. With numerous options available, it's crucial to weigh several factors to ensure you select panels that meet your specific needs. Let’s explore these considerations to help guide your decision-making process.

Key Factors to Consider

- Project Requirements: Begin by assessing the primary function of the panels in your project. Are they for structural support, aesthetic enhancement, or both? Define your project's goals and select panels that align with these objectives.

- Environmental Conditions: Consider the local climate and environmental factors. For instance, panels used in coastal areas should be highly resistant to corrosion due to salt exposure. In contrast, regions with high UV exposure may require panels with protective coatings to prevent fading.

- Budget Constraints: Evaluate your budget not just for initial purchase but also for long-term maintenance. While some panels may have a higher upfront cost, their durability and low maintenance needs can offer savings over time.

- Design and Aesthetic Preferences: The visual impact of your panels is paramount. Choose from a variety of finishes and textures to complement your architectural style. Whether you desire a sleek, modern look or a more traditional appearance, extruded aluminum panels offer a range of options.

- Supplier and Manufacturer Reputation: Research potential suppliers and manufacturers to ensure they offer high-quality products and reliable support. Companies with a strong track record in the industry are more likely to provide durable and well-designed panels.

- Compliance and Standards: Ensure that the panels meet local building codes and standards, especially concerning fire resistance and thermal expansion properties.

Comparative Analysis of Panel Types

| Panel Type | Advantages | Considerations |

|---|---|---|

| Standard Aluminum Panels | Lightweight, cost-effective, versatile in design | May require additional treatment for high UV exposure |

| Composite Aluminum Panels | Enhanced insulation, excellent durability, varied finishes | Higher cost, requires professional installation |

| Perforated Aluminum Panels | Unique aesthetic, good for ventilation, sound absorption | Limited structural support, may require additional framing |

| Corrugated Aluminum Panels | High strength-to-weight ratio, ideal for roofing | Industrial look may not suit all projects |

By carefully considering these factors and comparing different panel types, you can make an informed decision that enhances both the functionality and aesthetics of your project. For further insights into choosing the right panels, resources like Hurtubise Facades offer detailed guidance on the benefits and applications of various aluminum panels.

As you finalize your selection, remember that the right choice of extruded aluminum panels can transform your project, providing both durability and visual appeal. Next, we will delve into how these panels contribute to achieving durability and aesthetic excellence in modern construction.

Conclusion

Imagine a world where construction materials are not only functional but also contribute to the aesthetic and environmental goals of modern architecture. Extruded aluminum panels are at the forefront of this evolution, offering unmatched versatility and a host of benefits that make them indispensable in today's construction and design landscape.

These panels provide a unique blend of durability and design flexibility, allowing architects and builders to push the boundaries of creativity without compromising on structural integrity. Their lightweight nature simplifies installation and reduces transportation costs, while their inherent corrosion resistance ensures longevity even in the harshest environments. This makes them an ideal choice for both exterior and interior applications, from building facades to industrial flooring and signage.

Moreover, the aesthetic versatility of extruded aluminum panels is unparalleled. Available in a myriad of finishes and colors, they can be tailored to meet the specific visual requirements of any project. Whether aiming for a sleek, modern look or a more traditional style, these panels offer the flexibility needed to achieve any architectural vision. Their ability to be recycled without losing quality further underscores their role in sustainable construction practices.

As the demand for innovative and eco-friendly building solutions grows, extruded aluminum panels are set to play an increasingly vital role in shaping the future of architecture. They provide a strategic advantage for projects aiming for both aesthetic excellence and environmental responsibility.

In this landscape of innovation, Suqian Sunmay Aluminium stands out as a leader in the aluminum profiles industry. With a commitment to quality and a global reach spanning over 50 countries, Sunmay offers a diverse range of aluminum alloys and profiles, tailored to meet the specific needs of various sectors. Their cutting-edge technology and dedication to customer satisfaction make them a trusted partner for those looking to incorporate high-quality aluminum solutions into their projects.

In conclusion, extruded aluminum panels are more than just a material choice; they are a strategic decision that enhances the durability and aesthetic value of modern projects. As you consider your next construction endeavor, envision the possibilities that these panels can offer, and explore the innovative solutions provided by industry leaders like Suqian Sunmay Aluminium.

Frequently Asked Questions

1. What is the difference between extruded aluminum and sheet aluminum?

Extruded aluminum is produced by pushing heated aluminum through a die to create complex shapes, offering strength and design flexibility. Sheet aluminum is rolled flat and often used for simpler applications. Extruded aluminum typically provides a smoother finish and is stronger than cast aluminum, making it ideal for structural applications.

2. What are the problems with aluminum extrusion?

Common issues include die lines and scratches, which can result from worn dies or improper handling. These defects can be mitigated with proper maintenance and handling procedures, ensuring high-quality finishes. Regular inspection and cleaning of dies are essential to minimize these issues.

3. Why is aluminum extrusion so expensive?

The extrusion process involves precise machinery and skilled labor, contributing to higher costs. However, the benefits, such as reduced material waste and the ability to create complex shapes, often outweigh the initial expense. Additionally, the lightweight and durable nature of extruded aluminum can lead to long-term cost savings.

4. Is extruded aluminum stronger than cast aluminum?

Yes, extruded aluminum typically offers greater strength and fewer defects compared to cast aluminum. The extrusion process results in a uniform grain structure, enhancing its mechanical properties and making it suitable for load-bearing applications.

5. How do extruded aluminum panels contribute to sustainable construction?

Extruded aluminum panels are recyclable and energy-efficient, aligning with eco-friendly construction practices. Their durability reduces the need for frequent replacements, and their lightweight nature lowers transportation emissions, making them a sustainable choice for modern projects.